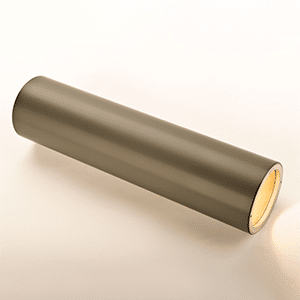

Anilox Wide Web

Rollers and Cylinders for Flexo, Litho, Coatings, and More

The Sandon Global wide-web reputation is respected worldwide because of in-house manufacture of anilox rollers, mandrels, sleeves, and end-rings for total quality control. The unique wide-web engraving solutions offer precision and consistency in volume transfer, line count, porosity and hardness characteristics.

High Definition Process 75° (iPro)

The Sandon Global High Definition 75º engraving (also known as iPro) harnesses the characteristics required to achieve vivid colors by controlling opacity while reducing dot bridging. Other benefits include:

- 75º engraving achieves a high line count reducing dot gain and bridging

- 0.4% dots allow printers to make the most of advancements in reprographics

- Vivid HD colors

- Inter-linking cells deliver HD print quality

- Consistent ink transfer, up to 600 mpm

- Reduce ink starvation

- Increased lifespan due to reduced wear and engraving damage

High Definition Process 61° (XPRO)

High Definition print is becoming ever more popular in wide-web applications, and the Sandon Global specialized 61º engraving (also known as XPRO) is ideal for both process and vignette print. Used typically with high resolution plates, robust cell peaks and channelled cell walls offer:

- 61º engraving reduces the risk of moire (or screen clash)

- Inter-linking cells deliver HD print quality

- Consistent ink transfer

- Reducing ink starvation, delivering vivid HD colors

- Precision volume control

- Reduced plugging

- Reduced wear and engraving damage

Heavy Solid & Coating (GMX Anilox®)

The Sandon Global patented engraving (also known as GMX Anilox®) has been designed to address the challenges of laying down special and heavy coatings including varnish, adhesives, and metallic inks. This versatile and unique engraving is protected under patent no. EP3408097B1 because of a design that allows for:

- Unique and efficient shallow cell design

- Delivering tactile and rough texture varnish applications

- Increase coat weights

- COCAL accurate coat weight formula

- Reduces cell blocking when using large coating particles

- Reduce vibration due to micro-finish cell polish

- Easy to clean

- Reduce annual spend on coatings, varnish, and lacquers

High Volume Solid (HVS)

Our High Volume Solid engraving (or HVS) was developed to enable high coat weights and ink deposits to be applied efficiently and consistently. Runs at high speeds without blocking, making it extremely popular with our wide web customers. Other advantages include:

- Deposit high coat weights and ink deposits

- COCAL predictor accurately predicts the volume or dry coat weight g/m² for your application

- Can be used when applying liquids such as lacquers and anti-mist

- Ink and coating particles flow between cell peaks

- Easy cleaning

High Volume Process (HVP)

The High Volume Process (also known as HVP) is an intermediate anilox that was designed to combine high line counts with high volumes for process solid and tone print. The elongated cell design allows for increased print latitude in comparison to conventional specifications. Key benefits include:

- Versatile engraving used for solids, mechanical tints, vignettes, fine line/text and clean reverse out print.

- Combines solids and tonal print on the same plate

- Reducing anilox inventory and press downtime

- Enhanced lay down, reducing pin-holing on solids

- Easy cleaning

- Improved wear characteristics, allowing cells to maintain good cell ratios and maintain their release characteristics

Combination (Fluid FP)

Our Combination engraving (also known as Fluid FP) is designed for use in wide-web flexographic print processes. The open nature of the engraving offers many advantages such as:

- A semi-channelled engraving enabling controlled ink flow

- High line counts for use on High Definition print

- Reduce dot gain

- Combines solid and tone on a single plate

- Good release characteristics

- Micro-polish finish

- Extended lifespan

Conventional 60° (Classic)

The 60° Conventional engraving (or Classic) is a multi-functional anilox and offers wide-web printers consistent print results for both process and solid print on a broad range of substrates. The open cell structure delivers excellent release characteristics.

- A 70% open cell structure aids ink flow

- Multi-functional engraving

- High cell wall ratio maximising ink release

- Process and solid print

Daetwyler is the only company that ensures both components (doctor blade and anilox) work optimally together, so ink transfer remains smooth and consistent – from the first impression to the last.